Nowadays no one is surprised to find that more and more areas of work are subject to automation. You do not need to rely solely on manual or visual supervision also in flat roof management. You can using state-of-the-art technologies and reduce the risk of human error to a minimum. In this article, we present the solution of Sense Monitoring implemented in Llentab steel buildings on the example of the Oknoplast manufacturing facility.

Due to economic reasons large-space buildings are designed with low sloping roofs, and water is drained by internal inlets. This solution, although proven, requires a proper work culture of the maintenance staff to check the drainage patency on an ongoing basis. Potential leaks often caused by mechanical damage of the roofing during snow removal are a similar hassle. Checking the allowable snow load also requires laborious manual measurements which are not very accurate. And the consequence of any negligence can be very costly or even tragic – if just to mention some recent events such as the collapse of the roof of the former Media Markt shopping centre in Gdansk or the collapse of the roof in a Lublin auto showroom or the widely publicized, biggest catastrophe in contemporary Poland in the building of the International Katowice Fair some years ago.

However, the risk of such incidents can be limited to a minimum by using automated measuring systems. “Knowing the typical problems faced by administrators and maintenance managers, we know that any defect can cause minor or major losses,” says Przemysław Gałązka, President of Sense Monitoring, manufacturer of the Sense S-One system. “That’s why we offer a service that registers potentially hazardous events on a current basis, including clogged drain inlets, soaking of insulation layers and the weight of snow.

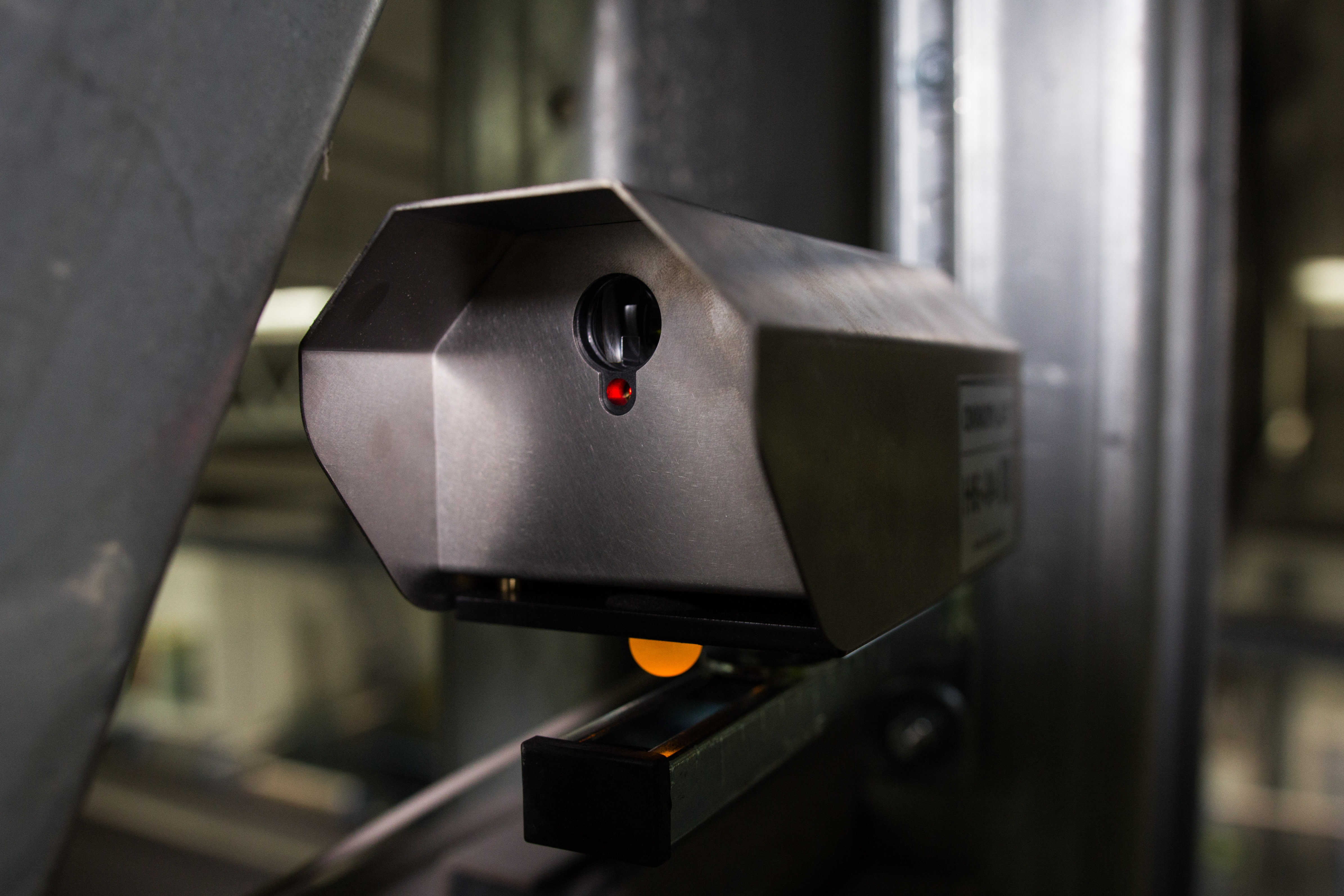

The Sense S-One system is based on a unique measurement method using relatively simple devices. “The measuring system consists of a network of laser sensors mounted at the support points of roof girders and measuring discs located at places of largest deflections. The measurement results are analyzed in a cloud which can be accessed by the user via a dedicated mobile application,” explains Artiom Komardin, a Sense Monitoring designer. “Our system helps the building administrator in daily work without putting any extra burden on the staff. When any indicators are exceeded we automatically inform the customer about it via email or SMS and protection measures can be taken before the situation goes out of control.

The effectiveness of the S-One system is confirmed by satisfied customers. “The decision to install Sense S-One was pretty obvious. “It is the only available system that doesn’t interfere with the structure (no drilling, no welding) and it doesn’t limit the facility’s operation, either” praises the system Paweł Wilczek, Infrastructure Engineer in the Maintenance Department of the Oknoplast manufacturing facility in Ochmanów near Kraków. “And the manufacturing operations in our facility are really at a maximum. We are a very innovative company and we are open to new technologies, so it didn’t take long to persuade us,” he adds.

The Sense S-One solution works well in many types of building structures, including steel buildings, the best of example of which is the mentioned above manufacturing facility of the Oknoplast Group. “The construction of this facility is quite a bit of the history of our company,” says Michał Szpilewski, President of Llentabhallen, manufacturer of steel buildings. “We started to work with the Oknoplast Group in the late nineties, building the first 3600 m2. Subsequent buildings were built, they have 38 000 m2 in total areal now,” he recalls. “The Llentab system was a perfect fit for the rapidly growing Oknoplast Group. All the buildings were tailored to the needs determined by the technology of production. Thanks to the ingeniousness of the group of our designers, we proposed optimal solutions which made it possible to easily combine the buildings that we built earlier with the newly built ones. Llentab’s sheet-wool-sheet wall cladding system with prefabricated holes which was used allowed us to move or dismantle some parts of walls improving communication between the buildings,” describes Szpilewski, adding at the end that: “Some of the facilities we constructed are open canopies constantly exposed to the weather conditions. Llentab steel buildings are ideal for such facilities because the whole structure is very well protected against corrosion. All structural elements are hot-dip galvanized. This ensures long life of the buildings even with adverse weather conditions. I think that this long cooperation have proved the good quality of Llentab’s buildings which fit in very well with ever-growing needs of customers. At the present time the Sense S-One system is used to monitor two manufacturing buildings made by Llentab for the Oknoplast Group. Next year it is planned to extend the system to cover the whole facility in Ochmanów. Interestingly enough, the Sense S-One system is offered on a subscription basis and does not require any substantial outlays.

The OKNOPLAST Group was established in 1994 in Krakow. Its objective is to create good looking windows of the best quality. The range of the offered products has also extended with the company’s development. Today the OKNOPLAST Group’s offer includes windows with unparalleled parameters, patio doors, exterior blinds, exterior doors, accessories for windows and doors and aluminium joinery. The quality of windows manufactured by the OKNOPLAST Group is confirmed by numerous awards and recognition of satisfied Customers around the world. The company is committed to innovation, so the offered products are characterised by not only a modern or classic design, but also the latest technology ensuring the best product performance. Nearly 25 years of experience, millions of sold windows, thousands of showrooms across the country and abroad – all this makes the OKNOPLAST Group one of the most recognizable brands in the window industry, and it obliges!

SENSE MONITORING Sp. z o.o. is a young company established by experienced engineers in the field of construction, land surveying and information science. The company has won numerous distinctions, including but not limited to winning the second edition of the Startapy w Pałacu [Startups in the Palace] competition or winning the Smart City category in the European Startup Awards 2017. It is the only Polish startup in the Top10 at the Wolves Summit. The Sense S-One system is currently used in buildings with a total area of 144,000 square meters including but not limited to logistic buildings, large-area stores and manufacturing plants. Next year the company plans to enter the Scandinavian and Eastern European markets.

LLENTABHALLEN has operated on the Polish market since 1992 year and has built more than 1,800 steel buildings. The Swedish LLENTAB brand has been known in Europe for over 45 years thanks to the construction of more than 10,000 steel buildings. The company has a flexible approach to the design, manufacture and assembly of steel buildings taking into account individual customer needs, using unique solutions that have a measurable impact on the functionality, durability and appearance even after many years of use. LLENTAB steel building are used in a variety of ways as manufacturing facilities (including facilities for the food industry), warehouses (including high storage facilities), large-area stores, showrooms, hangars, livestock buildings, etc. Imagination is the only limit to the appearance of a steel building in the LLENTAB system.