William Edwards Deming, a globally renowned American statistician who gained recognition for his groundbreaking work in the field of statistical quality management, considered quality to be a major success factor: “Improve quality, you automatically improve productivity. You will succeed in the market with a lower price and higher quality. You will succeed commercially and generate jobs.” The management team of LLENTAB, spol. s r.o., the leader on the Czech steel hall market, is also convinced about the importance of quality. This is why it organises and manages quality control comprehensively and systematically.

“Our quality control system has several parts and subsystems,” says Blanka Sedláková who is in charge of quality management at the firm, adding: “One of them is ‘LLENTAB Inside’, a process-oriented operating system that principally meets the requirements of the ISO 9001 standard. We inspect the deployment and efficiency of our processes and their impact on the required result. This system contains process maps, directives, instructions and model documents. By applying and observing this operating system, we want to be accessible, flexible and able to always respond to customers’ requests.

Prior to accepting an order, the management team always makes sure that it has access to resources needed to deliver the job successfully and satisfy its obligations. Orders are always delivered on the basis of the prior quotations, and obviously in accordance with law and master agreements. The firm also works only with products and services from carefully selected suppliers.”

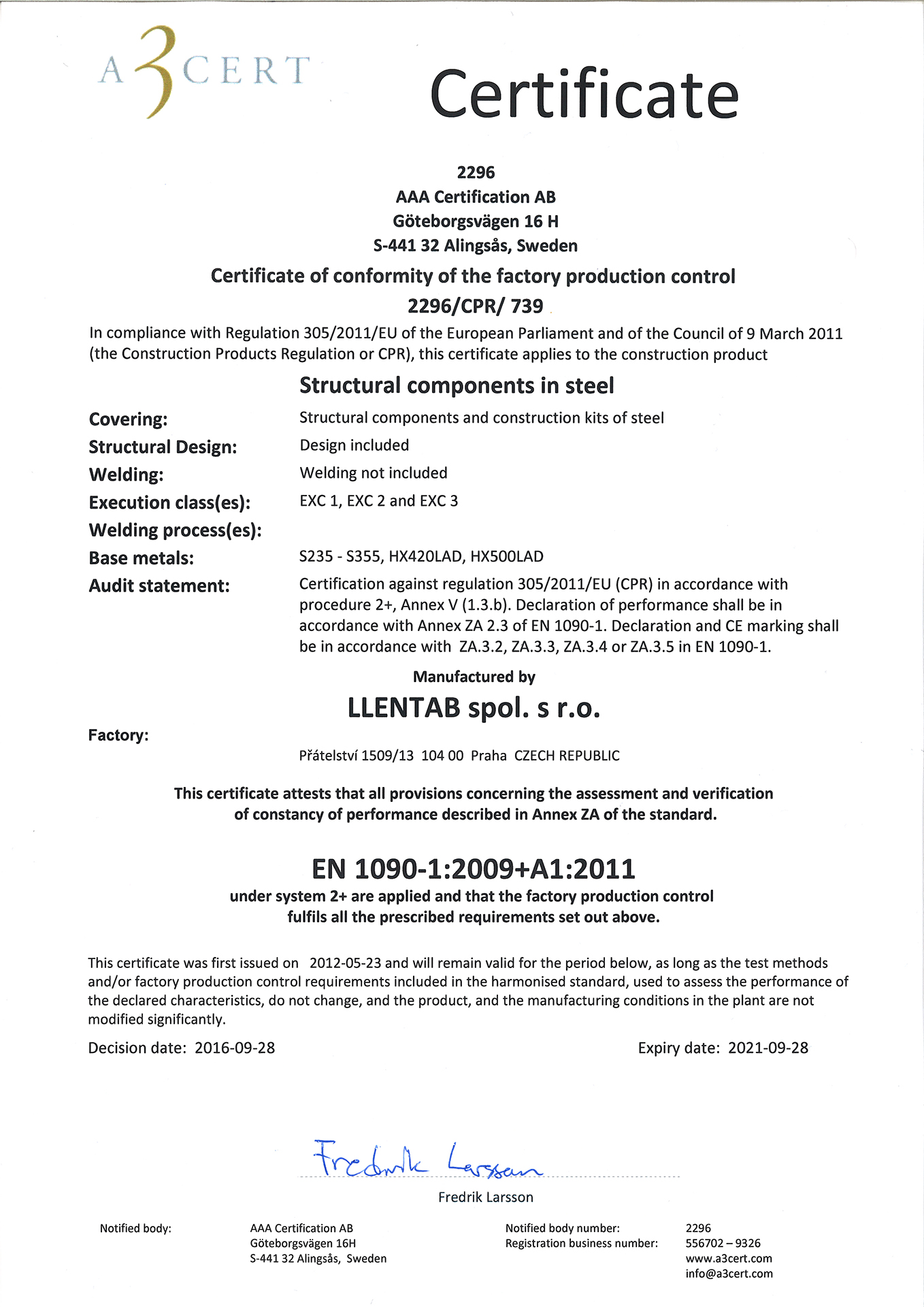

The next part of quality control is design and manufacturing, which is certified to EN 1090-1. This means that LLENTAB is authorised to mark its steel buildings/products “CE”. This is because the manufacturing at the parent company, LLENTAB AB in Sweden, was certified to the aforesaid European standard (EN 1090-1, Mandatory CE Mark for Structural Metallic Components). The certificate was bestowed and is verified by the Swedish notified company, AAA Certification AB, and since the CE mark is valid in all EU member countries, Czech customers can be sure that LLENTAB steel products and structures are technologically reliable and safe.

What is more, the quality of installation and the adherence to occupational health and safety (OHS) rules is inspected in the field during the erection of LLENTAB buildings. Mr Václav Konečný, who was the primary supplier of installation work at the beginning of LLENTAB, spol. s r.o., helped with the introduction of the field quality control system, putting his experience with steel hall assembly to good use in quality control. LLENTAB currently outsources quality control from CIVOP s.r.o. whose services are tailor-made to LLENTAB, spol. s r.o.’s requirements and needs. CIVOP System® is a comprehensive and constantly expertly developed system of outsourcing occupational health and safety (OHS), fire protection (FP), environment protection and statutory inspections of equipment. The quality of assembly is inspected and the safety culture is being improved with the aim of creating safe workplaces and ensuring safe conduct. As a result, the customer is always assured that a LLENTAB structure is assembled in line with the standard, in safe conditions and in the required quality. “We started working with CIVOP s.r.o. in OHS and FP in 2009 as regards our own office building and offices in Prague-Uhříněves. In January 2016 we extended our cooperation with requirements for quality control regarding installation and OHS directly on our sites including on-site consulting and expert assistance in the event of government authority inspections,” says Blanka Sedláková.

In particular, LLENTAB sites are inspected for:

- Tightness of bolt joints in observance of the ČSN EN 1090-2+A1 standard and the tolerance defined by an internal instruction. The required tightening torque of tightened bolt joints is measured using a regularly calibrated digital torque wrench;

- Pillar verticality and straightness is measured using a digital water level;

- The keeping of the site log and quality control documents defined by the “LLENTAB Inside” internal operating system;

- Observance of OHS rules – e.g. breath analysis to detect the presence of alcohol in blood, safety and fire signage, statutory inspections of tools and equipment including regular checks and reports.

The process starts with commissioning an inspection of a specific site, followed by the actual inspection, and the inspection output is then submitted for processing. The inspection outputs (practical situations occurring on sites) are a source of topics to be discussed during training sessions. “In order to be able to require a specific quality level, we organise technical training sessions and regular meetings with our collaborating suppliers. At the same time, we request our suppliers to submit statutory training certificates, medical fitness certificates and technical qualification certificates,” says Blanka Sedláková. The training sessions include, for example:

- LLENTAB’s prescribed process and working procedures;

- New features in the LLENTAB system;

- Addressing specific site situations in the presence of LLENTAB designers and technicians;

- Collecting suggestions and ideas for improvement stemming directly from the construction of halls;

- OHS and FP.

We have been so satisfied with our cooperation with CIVOP in the aforesaid extent that, with effect early in 2018, we are launching this inspection system at our subsidiary, LLENTAB Slovakia s.r.o. CIVOP Slovakia s.r.o. will provide the inspections on the Slovak market.

According to Blanka Sedláková, the system of tracking inconsistencies is an important part of quality control. “We extend and improve the system so as to minimise and prevent the occurrence of inconsistencies. We track inconsistencies using a database system that allows us to efficiently evaluate frequently reoccurring or critical types of inconsistencies. The records include the resolution of an inconsistency with a specific solution that is of the same quality as the original design. With this system, we pursue several goals concurrently – we want to satisfy the specifications and defined standards, respect the customers’ needs to the maximum and ensure the prosperity of our company.” By striving to achieve the required level of quality and observing OHS requirements, LLENTAB wants to achieve satisfaction on the part of its customers/investors and build long-term positive relationships with them. With the inconsistency tracking system described above, LLENTAB can always show the client how an issue was resolved. The quality control system for LLENTAB steel buildings includes the standards of recognised independent authorities on the local market. In the Czech Republic, these are authorised testing institutions: Technický a zkušební ústav stavební Praha, s.p. (Technical and Test Institute for Construction; TZÚS Praha) and PAVUS, a.s. They test products or product components, in effect setting the standards for subsequent quality control.

The quality control system at LLENTAB, spol. s r.o. draws on an elaborate system in place at the parent company, LLENTAB AB in Sweden. “Our parent company and its subsidiaries have a similar quality control system, although it is always adapted to the local implementing regulations and customary practice. For example, we have applied a process of controlling our own work based on our experience. This means that we use control documents based on the LLENTAB Inside process-oriented operating system, which workers use to check their own work once completed. It starts with checking if the material supplied is complete, continues with checking bolted connections and the verticality of pillars and other parameters, and ends with the final signature that confirms that everything is compliant with the standard and of the required quality. These control documents are assessed, issues are addressed where necessary and then the documents are archived along with the site log,” Blanka Sedláková explains.